HIGH PERFORMANCE

& TECHNOLOGIES

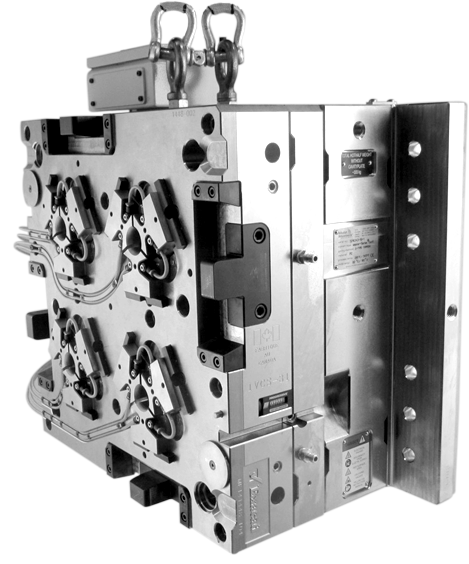

We design and manufacture single and multi-material plastic injection molds

We create solutions for: in-mold assembly processes and integration of secondary operations within the molds for automated molding productions

Custom manufacturing of molds for use in industry

Custom manufacturing of systems and parts for plastic injection molding

ABOUT US

Become more productive and more competitive From its very beginning in 1995, Exacad innovates by manufacturing plastic injection molds that features ingeniously integrated cavities to maximise the capacity of the molded parts. Thanks to their small size, our molds are reliable, high-performing, low in energy consumption and designed for quick and easy maintenance.

In addition to this unique concept on the North American market, Exacad proposes leading-edge technologies for the manufacturing of multi-shot plastic injection molds, in-mold assembly processes and the integration of secondary operations for automated productions.

TECHNOLOGIES

Because each molding projects is unique Technology driven to best meet your needs for maximum molding performances. Exacad’s distinctive approach contributes to an optimization of your overall cost of production.

Our understanding of your needs relies on our ability in gathering, synthesizing and analyzing your data. With Exacad, your company will benefit of creative solutions resulting in high-quality and high-performance plastic injection molding.

PORTFOLIO

Creator of sustainable and tailor made solutions Exacad's customers include, among others, manufacturers, molders, designers, and research centers from various industries. They selected us for our understanding of their needs and our ability to implement ingenious solutions.

Exacad’s customers appreciate the simplified molding processes that we have developed. They recognize the reliability of our plastic injection molds and equipment that will serve them in molding their long lasting products. Our customized approach allows us to design and implement the most appropriate technologies for your needs, resulting in a reduction of your total cost of production and higher profitability.

OUR PASSION,

YOUR PROJECTS!