PHARMACEUTICAL PLASTIC VIALS

Our customer, a SME manufacturer, specializes in the Eco design of various plastic vials for the pharmaceutical industry. His approach is similar to Exacad, as he strongly believes in the importance of reducing energy consumption and ecological footprint.

1. THE NEED

- Support and understanding throughout the project life cycle

- Maximize global use of the production equipment

2. THE SOLUTION

- Design and manufacture high performance plastic injection molds geared towards energy reduction

- Maximum use of all available production equipment.

- Provide on-site presence and support throughout the project’s life cycle

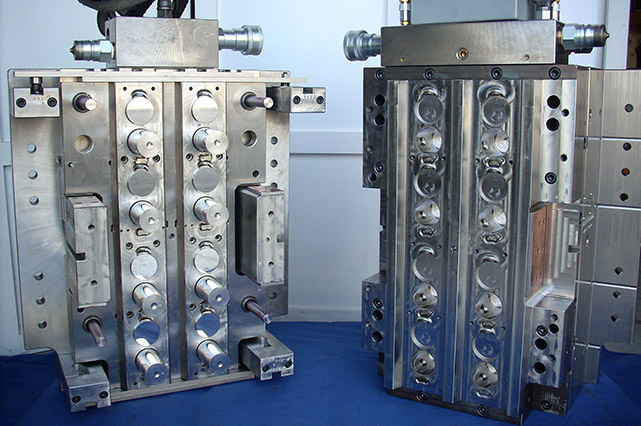

3. TECHNICAL SPECIFICATIONS

- Ultra-rigid and compact molds featuring 16 cavities in the space of 12

- Integrated conformal cooling channels within the cores to take advantage of the highest possible speed of the injection molding machine

- High-speed movement and no wear shock free cams achieved with needle rollers on smooth rails

4. THE BENEFITS

- Significant energy savings

- Reduced mold downtime due to quick and easy maintenance

- Production yield increase: 25% more parts per cycle