PLASTIC ELECTRICAL CONNECTORS

Our customer, a global leader in the energy industry, designs, produces and commercialises reliable plastic parts for electricity connection and distribution.

1. THE NEED

- To successfully mold multimillion parts per year with a fireproof resin known to corrode hot runner systems

2. THE SOLUTION

- Design and manufacture plastic injection molds without using hot runners, while maintaining a quick cycle time

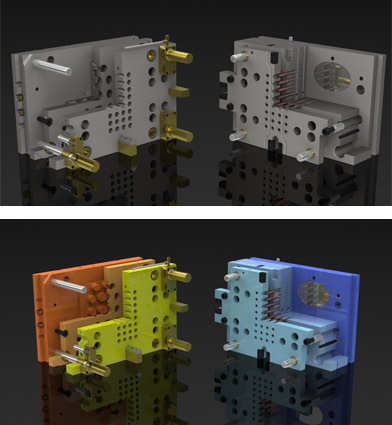

3. TECHNICAL SPECIFICATIONS

- High-speed 3 plate molds with pneumatic sequencing, no latches or springs required

- 64 cavities in the space of 48

- Exclusive 3 plates runners unmolding system without the need of sucker pins

4. THE BENEFITS

- Stability in production without degrading the fireproof resin

- Reduced mold downtime due to quick and easy maintenance

- Improved productivity with high molding performance: multimillion cycles

- Reduced global production costs