MINIATURE PLASTIC MECHANISM

Our customer, a division of a multinational corporation, produces plastic decorative accessories for the mass consumer market.

1. THE NEED

- Zero reject production

- 1 million parts per day per mold of small mechanical components

- No direct labor costs

2. THE SOLUTION

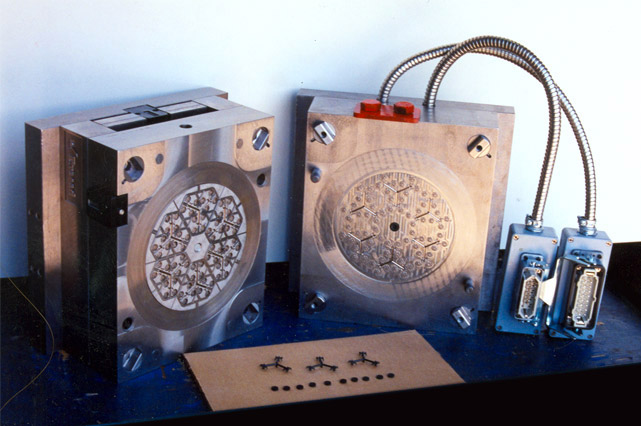

- Design and manufacture plastic injection molds for multimillion cycles

- Reduction of the runners weight

- Clever use of both hot and cold runners

- Complimentary engineering of the part to achieve zero downtime molding

3. TECHNICAL SPECIFICATIONS

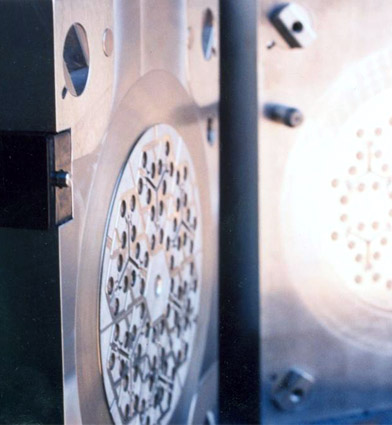

- Product optimization: reduction and homogenization of the wall thickness and shut-offs integration for easy unmolding of the parts

- Multiple ultra-compact plastic injection molds

- An injection system that combines hot runners and miniature cold runners

4. THE BENEFITS

- Ongoing fully automated production: 1 million parts per day per cycle

- Reduced resin consumption

- Reduced plastic overage regrind

- Quick ROI