TECHNOLOGIES

OPTIMIZE YOUR OVERALL

COST OF PRODUCTION

We create for you what others cannot even imagine

Because each molding projects is unique — Technology driven to best meet your needs for maximum molding performances. Exacad’s distinctive approach contributes to an optimization of your overall cost of production.

Our understanding of your needs relies on our ability in gathering, synthesizing and analyzing your data. With Exacad, your company will benefit of creative solutions resulting in high-quality and high-performance plastic injection molding.

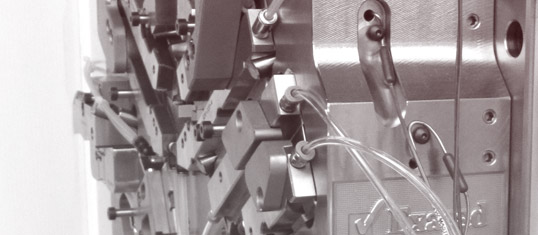

MULTI-MATERIAL MOLDS

Molding made easy

Pre-assembled multiple resins into a single shot

Calibration and precision machining +/‐ 0.0002" for robust, long lasting parting lines

Enables the overmolding of 2 or more resins without direct labor — Can be used on a dedicated injection molding machine, or adapted to a standard machine with the addition of secondary equipment. Regardless of the solutions we offer, you will benefit of a reduced overall production costs, and, in specific cases, of reduced manual labor and other project costs.

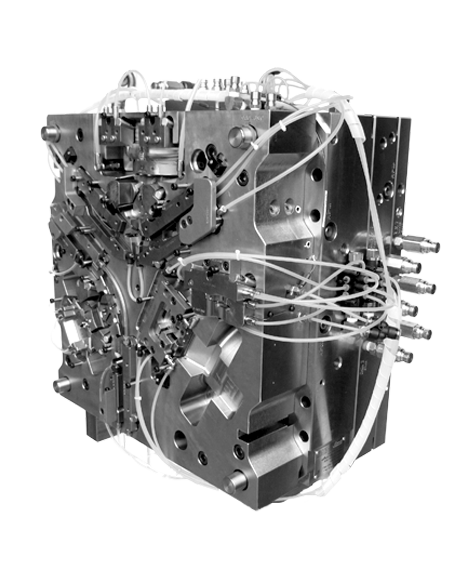

ULTRA-RIGID & COMPACT MOLDS

Molding cycles that measures up

to you ambitions!

Half-weight molds

Half-size injection molding machines

Maximise capacity of molded parts on the same molding machine

We master technologies and deliver molds made with our exclusive engineering and know-how to meet your specific needs – The ingenious structure of our molds integrates mechanisms such as centering alignment and core stabilization for a system that is compact, precise, long lasting and designed for quick and easy maintenance. Purchasing an Exacad solution means: lighter molds that can be used on smaller presses. This in turn will reduce your total cost of production for and increased profitability.

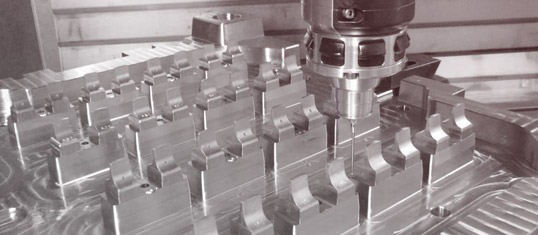

PORTFOLIOLED LIGHTING

Efficient & cost-effective optical light distribution

Plastic injection molding of pre-assembled LED lenses

Exclusive technology for high-efficiency lighting

Customized optical light distribution – Take advantage of our exclusive machining technology to develop your own optical lighting system. We provide tailor made pre-assembled LED lenses in a single module for quick installation.

IN-HOUSE PLASTIC INJECTION MOLDING STATIONS

The answer to your manufacturer’s needs

No need for skilled workers

Small surface molding stations

Requires minimal supervision

Production on demand when you need it

Be in control of your production — In-house small surface molding stations without specialized workforce. We deliver tailored solutions specifically designed to fulfill your variable needs for manufacturing products families, and we provide constant support throughout the complete project life cycle. You will also benefit from onsite training at the time of the project start-up.

PORTFOLIOYOUR SUCCESS

IS OUR ULTIMATE GOAL